Products

Hot Products

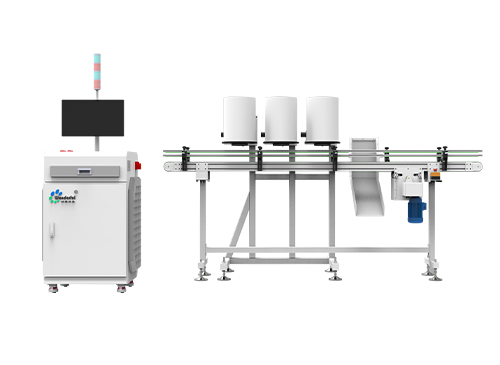

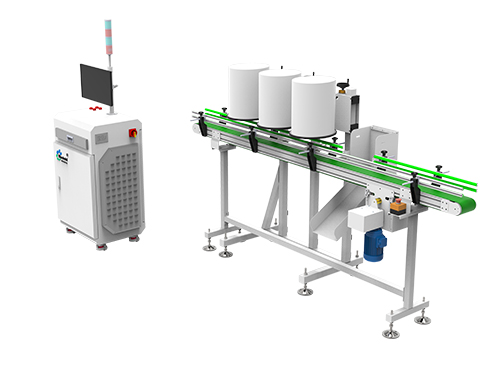

Metal Caps&Closures Visual Inspection Machine

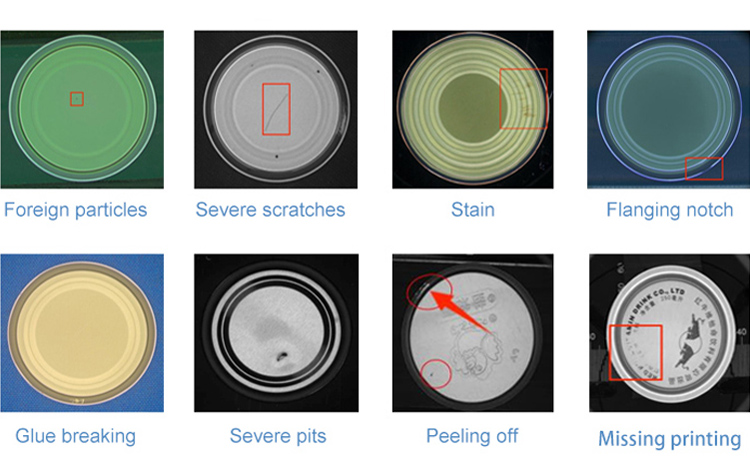

The metal caps&closures visual inspection equipment uses 2 cameras to detect defects on the glue injection surface and non-glue injection surface, such as damaged, dirt, severe scratches, severe cracks, deformation and other defects.

Send Inquiry

Product description

Introduction:

The metal caps&closures quality inspection machine is usually based on machine vision technology. It is a fully automatic inspection equipment specially used to detect the quality of metal caps&closures, such as twist-off closures, aluminum caps, tinplate caps.

At the same time, it is also an indispensable detection equipment in modern industrial production. Its advanced machine vision technology and the convenience of automated operation provide a strong guarantee for the improvement of product quality.

Technical parameter

| Detective Defects | Damaged,dirt,scrach,crack,deformation... |

| Inspection Position | Caps&closures edge,surface |

| Inspection Speed | 0-2000 cans/min |

| Inspection Accuracy | 0.5mm |

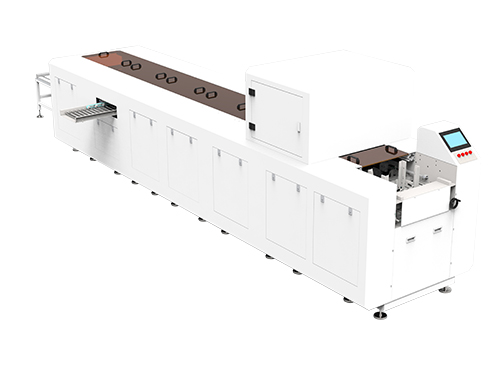

| Machine Structure | Integral/spit machine |

Detect Defects

Main features:

① Efficiency: Visual inspection equipment can achieve high-speed and continuous online inspection, greatly improving inspection efficiency.

② Accuracy: Using machine vision technology, visual inspection equipment can achieve detailed inspection of different angles of metal caps, and the recognition accuracy is much higher than manual inspection, reducing the possibility of missed inspection and false inspection.

③ Stability: Visual inspection equipment can work 24 hours a day, with stable and reliable performance, fully meeting the needs of large-scale production.

④ Intelligence: Advanced visual inspection equipment is also equipped with an AI deep learning system, which can continuously learn and optimize the inspection model to improve inspection accuracy.

Advantages:

① Ensure product quality and food safety

Consumers are increasingly concerned about food safety and quality. The metal caps&closures inspection machine can provide accurate and reliable test results, giving consumers greater confidence in your products

② Improve production efficiency

Metal caps&closures inspection machines have a high degree of automation, simple and convenient operation, fast and stable equipment, and can complete the detection of a large number of samples in a short time, ensuring testing efficiency and accuracy.

③ Promote the healthy development of the industry

By improving the quality and safety of products, it can not only enhance the competitiveness of enterprises, but also benefit the overall development of the industry

④ Embodiment of environmental protection concept

By optimizing production processes and improving inspection efficiency, visual inspection equipment helps reduce energy consumption and waste generation, which is in line with the concept of sustainable development. Besides, the use of visual inspection machine can reduce dependence on harmful substances such as chemical detection agents and reduce pollution to the environment.