The Advantages and Applications of Visual Inspection Machines

2025/06/16

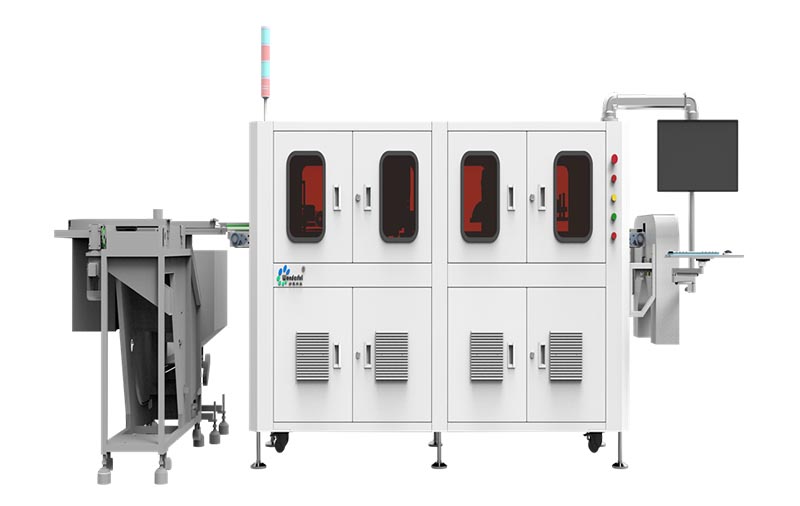

The flagship product of our company is Wonderful Tech. Vision Inspection Machine, that is suitable for the plastic bottles, plastic caps, metal bottles, metal caps, printing tinplate industry.

Advantages: Excellent configuration, strong calculation ability, high accuracy, comprehensive software functions, easy operation.

Inspection Defects: Deformation, foreign matters, open welding, split edge, oil stains, scratches, notch, internal gum flow, gap, black spots, dirt, etc.

Application field:

Packaging industry

Packaging integrity inspection: Check whether the packaging bags and boxes are well sealed and undamaged to prevent the products from being contaminated or damaged during transportation. For instance, conduct a sealing test on the snack packaging bags to ensure there is no air leakage.

Printing quality inspection: Check whether the printed content on the packaging is clear, whether there are any typos, and whether the color is accurate, etc. For instance, the printing quality inspection of beverage bottle labels ensures the accuracy and aesthetic appeal of the label information.

Logistics and warehousing field:

Package sorting: Vision Inspection machine recognizes the barcodes, QR codes or text information on packages, automatic sorting and classification of packages are achieved, improving logistics efficiency. For instance, the express sorting center uses visual inspection equipment to quickly identify the destination of the packages and distribute them to different conveyor belts.

Goods appearance inspection: When goods are entering or leaving the warehouse, check whether there is any damage, deformation or other conditions on the goods to reduce logistics disputes. For example, conduct an appearance scan of the goods packed in cartons and record whether there are any compression marks.

The electronics and semiconductor industry:

Semiconductor wafer inspection: Detect defects, impurities, scratches, etc. on the surface of wafers to ensure their quality. In the front-end process of chip manufacturing, high-precision vision equipment can identify defects at the nanometer level.

LCD and OLED screen inspection: Check the screen for defects such as bright spots, dark spots, dead spots, and scratches to ensure the quality of the display panel. For example, on the production line of mobile phone screens, vision inspection machine recognizes the barcodes will conduct a comprehensive inspection of each screen.

Our company not only provides excellent products, but also has a harmonious team atmosphere and a variety of company activities. Just last week, we staged the 2025 Summer Sports Meeting.

Events:

Team competition (Basketball, 4* 100-meter relay race, passing the ball, arrow throwing);

Individual competition (rope skipping, badminton, 1000-meter long-distance running)

During the sports meeting, all departments worked in unity and cooperation, and the athletes performed at a high level. Sports meeting promoted the sports spirit, enhanced physical fitness, fostered unity and facilitated development.